Case Studies

From initial ground works through to final fit-out, Moorcroft Construction Ltd undertakes all aspects of the building process. A vast range of projects successfully completed within various sectors are highlighted in the case studies below

Should you have any questions or would like to discuss a project call our team today on 0151 355 8121 or alternatively email us at enquiries@moorcroftltd.com

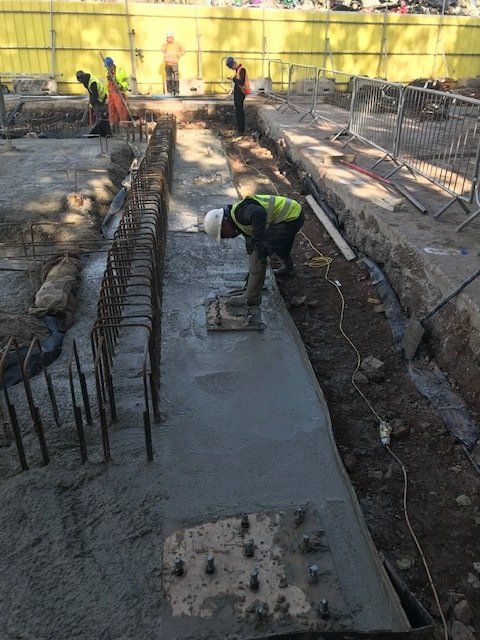

TATA Chemicals Europe - Middlewich

New Boiler House - 28 weeks

Moorcroft carried out the construction of heavily reinforced concrete foundations, these consisted of pile caps and ground beams, along with a reinforced concrete slab finished to tight tolerances including integral pits and machine base plinths with cast in HD Bolts to a tolerance of +/- 2mm, chimney stack foundation and external works.

This was a challenging contract involving the diversion of a live sewer which was over pumped to maintain flow and ensure the running of the site went uninterrupted throughout the early construction phase.

The deep drainage and grouting of redundant drains were all successfully completed ahead of the main works.

JH Willis - Ince, Chester

Tank Farm - 16 weeks

Construction of a new bulk waste liquid processing plant. The works involved bulk earthworks followed by the construction of a cleverly designed set of reinforced concrete holding tanks and tanker delivery reception yard for the processing of bulk liquid waste to be processed for agricultural use.

Moorcroft worked hand in hand with both the client and the designers to establish an economical robust design comprising of a group of waterproof tanks constructed within a recessed earthworks bunded slab, encapsulated within a waterproof liner. The structure was completed with a series of reinforced concrete plinths designed to carry 5 50-tonne storage and processing vessels.

S Norton & Co. Ltd - Liverpool

Pre-shredder Plant - 18 weeks

Moorcroft was awarded the works to construct the heavily reinforced concrete sub and super structure built on a CFA Piled Foundation with cast in HD bolts in preparation to receive perimeter ’blast walls’ and a bespoke metal shredding machine required to speed up the processing of scrap metal.

Heavy plant was required for the removal of existing substructures and the grubbing out of a disused unchartered culvert before the construction of a piling mat in preparation for piling.

The project was successfully delivered to the required timescale to meet the predetermined delivery date of the new bespoke metal shredding machine.

S Norton & Co. Ltd - Seaforth, Liverpool

HMS Cleanline - 20 weeks

Construction of a heavily reinforced concrete foundation built on PC piles and adjacent substation foundation, and associated ducting on Liverpool’s Canada Dock in readiness for the installation of the newly designed HMS shredding machine that has been designed to enhance the quality of processed scrap metal ensuring the client stays ahead of the competition.

This contract was completed ahead of the client’s tight time scales and in compliance with rigorous health and safety requirements associated with specialised piling, reinforced concrete foundations and a complex super structure whilst working adjacent to the Irish Sea.

Unilever - Wirral

RC Bunded Slab, Plinths, Drainage & Service Diversions - 16 weeks

Moorcroft undertook works to construct a reinforced concrete bunded slab with sumps and plinths with cast in holding down bolts ready to receive new infrastructure and steel pipe bridges.

Enabling work involved the removal of existing concrete slabs and sub-structures and the preparation of ground including service diversions and new drainage. The construction of a concrete bunded slab with sumps, and plinths with cast in holding down bolts ready for steel pipe bridges.

The project was successfully delivered on time while ensuring that business continuity was maintained.

Cholmondeley Estates - Helsby

Helsby Bridge - 8 weeks

Moorcroft carried out the reconstruction of a concrete bridge deemed structurally unsafe for vehicles spanning over the ‘Old Chester Road’ in Helsby.

The existing bridge surface was excavated and loaded into wagons to expose the old concrete bridge deck. A crash deck was erected beneath the bridge to support the failing structure. Extreme care was taken to remove the existing concrete deck in sections to prevent damage to the existing stone parapet walls.

The crash deck was then lifted to the bridge soffit design height and a new reinforced deck constructed. The bridge sides were then fitted with Armco Barriers and Gabion Baskets utilising locally sourced sandstone before the form work was removed and the bridge handed over to the client.

Peel Ports/ ECOCEM - Runcorn

Civil engineering/Import Terminal, Silos and Substation

Following a detailed tender process, Moorcroft was contracted to construct a silo with weighbridge, office, substation and infrastructure connected to the dock system for the import of cement. The project was commissioned by ECOCEM in a joint venture with Peel Ports. As the principal contractor, Moorcroft took responsibility for the project management including service delivery, governance and health and safety.

Working within the tight confines of a fully operational dock system, Moorcroft managed of a number of specialist sub-contractors.

Due to the ground conditions and the sub surface dock walls, Moorcroft worked closely with the clients and the design team to provide cost effective methods for piling and substructures to enable the project to progress.

Project delivery was time bound due to the pre-arranged arrival of ships into the terminal for the distribution of product.

Moorcroft delivered phase 1 of the project on time to an agreed budget, resulting in the commercial deadlines for the client being met.

As a result of the success of phase 1, Moorcroft was awarded phase 2 which involved the provision of an additional silo, base weighbridge and infrastructure.

Unilever - Wirral

Concrete Floorings and Coatings

Unilever required Moorcroft to successfully co-ordinate and deliver, as part of a factory-wide refurbishment project, reinforced floor slabs for their new product lines.

The project had to be carried out adjacent to the company’s live plant, ensuring production and business continuity was maintained at all times in a safe and effective manner.

Moorcroft worked with the on-site team to successfully install highly polished floor slabs to FM2 tolerances covering an area of over 15,000m2. Our work included the breakout, excavation and disposal of the existing floors. Moorcroft successfully worked with the Unilever team to ensure the project came in on time and on budget.

Cargill PLC - Liverpool

Warehouse facility

During a systems review at Cargill’s grain storage facility in Liverpool, it was deemed there was a requirement to provide new entrance and exit canopies to the large existing grain store.

Following the continued development of Cargill’s own safety policy, Moorcroft was asked to provide dry and safe facilities and access to un-sheet and re-sheet grain haulage wagons. Two portal frame buildings were constructed and clad, including foundations and new concrete road slabs, one at each end of the storage facility.

The project involved working in a tight location near to the dock side in an operational environment containing hazardous substances and processes.

The project was delivered ensuring business continuity was maintained, balanced with safe and effective systems of work.

We worked with the onsite team resulting in an operationally effective facility being delivered on time and within budget.

Baker Hughes - Kirkby

Concrete Flooring, Drainage, Loading Bays & Infrastructure

Moorcroft was chosen by Baker Hughes to be the Principal Contractor for the construction of a concrete overlay slab for the storage of Intermediate Bulk Containers (IBCs) to include dock levelers, drainage, underground tanks, fencing and gates and associated infrastructure.

Pre-construction technical issues were resolved collaboratively with the client and the design team, working to fixed budget and tight deadlines. The project was carried out in a restricted location on a top tier COMAH site in an operational environment containing hazardous substances and processes.

The project was delivered on time and on budget and was acknowledged as a good example of collaborative problem solving before and during the project. Health and safety considerations were primary in the planning and implementing stages adhering to the CDM 2015 regulations throughout.

Private Developer - Cheshire

Luxuary Residential Home

Moorcroft was chosen to develop existing unoccupied farm buildings and convert them into 4 3-storey luxury homes. The development included external landscaping and Section 278 works for the entrance to the development. The project was delivered under CDM Regulations 2015.

The existing buildings required partial demolition and bespoke engineering solutions were developed to comply with the strict planning conditions, environmental needs, and the high technical specification demanded of the build.

This was a real team effort. Our own skilled in-house workforce collaborated closely with the client as well as specialist contractors, designers and structural engineers to deliver the luxury bespoke homes situated in landscaped grounds complementing and enhancing the local area.

Saint-Gobain Isover - Runcorn

Civil Engineering, Tank Farm & Chemical Coatings

Moorcroft was chosen by the client to construct a high quality piled concrete tank farm including holding tanks comprising of bund walls, galvanised access gantry, foul water drainage and a specialist concrete protective coating to all concrete surfaces and surrounding infrastructure. We were tasked with managing and coordinating the project in a safe and effective manner.

Working in a confined location in an operational environment containing hazardous substances and processes, Moorcroft ensured that business continuity was maintained. Technical issues were resolved collaboratively with designer, client and contractor which included pile design and location and selection of appropriate chemical coating.

The project was delivered on time and on budget and was acknowledged as a good example of collaborative problem solving. Moorcroft was able to successfully engage its specialist supply chain and work with onsite staff leading to a successful outcome.

Balfour Beatty

Infrastructure & Utilities

In order to supply power to a new multi-million pound facility, Moorcroft was asked to provide a new cable trench for an 11Kv cable supply across the existing site and through to the new manufacturing complex.

Working under strict safety procedures and protocol, this contract involved the excavation of a service trench within a highly sensitive nuclear facility. The process involved the careful excavation of a 2 kilometre cable trench including surface reinstatements, working around multiple live services, while maintaining full site functionality for the client.

The project involved close collaboration with the client to overcome a number of complex technical challenges.

The project led the way for the use of vacuum excavation on site as a safe method of working and has led on to additional cable excavation works.

Baker Hughes - Kirkby

Concrete Flooring, Drainage, Loading Bays & Infrastructure

Moorcroft was chosen by Baker Hughes to be the Principal Contractor for the construction of a concrete overlay slab for the storage of Intermediate Bulk Containers (IBCs) to include dock levelers, drainage, underground tanks, fencing and gates and associated infrastructure.

Pre-construction technical issues were resolved collaboratively with the client and the design team, working to fixed budget and tight deadlines. The project was carried out in a restricted location on a top tier COMAH site in an operational environment containing hazardous substances and processes.

The project was delivered on time and on budget and was acknowledged as a good example of collaborative problem solving before and during the project. Health and safety considerations were primary in the planning and implementing stages adhering to the CDM 2015 regulations throughout.

Cargill PLC - Liverpool

Warehouse facility

During a systems review at Cargill’s grain storage facility in Liverpool, it was deemed that there was a requirement to provide a new entrance and exit canopies to the large existing grain store.

Following the continued development of Cargill’s own safety policy, Moorcroft was asked to provide dry and safe facilities and access to un-sheet and re-sheet grain haulage wagons. Two portal frame buildings were constructed and clad, including foundations and new concrete road slabs, one at each end of the storage facility.

The project involved working in a tight location near to the dock side in an operational environment containing hazardous substances and processes.

The project was delivered ensuring that business continuity was maintained, balanced with safe and effective systems of work.

We worked with the onsite team resulting in an operationally effective facility being delivered on time and within budget.